Every once in a while I get a call asking, “what size spokes do I need to build a wheel”. Trying to describe the process of measuring and calculating over the phone seldom goes well for either party. Here is a step by step guide to how I do it here at the Bicycleman.

Usually you can get the numbers you need off the internet. I do a search for “wheel building dimensions for a _______ rear hub” and most of the time if it is a modern hub I will be able to find it. If not, this is how to come up with what you need.

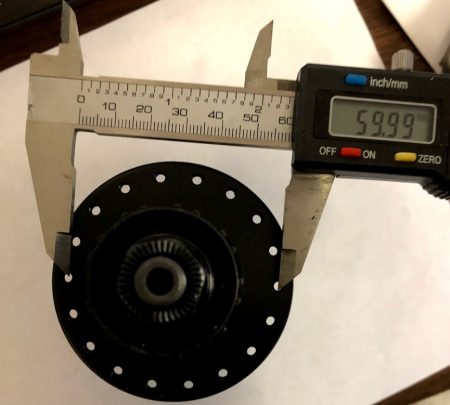

First measure the hub flange diameter in millimeters. Buy a cheap digital caliper down at Harbor Freight for $10 or so and measure from the center of a spoke hole to the center of the one on the opposite side of the hub flange.

In this case I measured around 60mm. It’s a good idea to check the other flange to make sure it is the same. Sometimes one flange will be smaller than the other and you need to keep track of which is which. The next thing you need to know is what the overall width between the locknuts is on your hub. Often on recumbents it is 135mm but not always. Measure from the outside face of the locknut on one side to the outside face of the other side. This hub measured 135mm.

Now comes the tricky part. We need to know the distance from the center of the hub to the center of the hub flanges. To do this you need the take the distance from one lock nut face to the other and divide by two. In this case 135 divided by two equals 67.5mm. Then you set and lock your calipers to 67.5mm and set one end of the jaws of the caliper on the face of the locknut and use the other to scratch a small mark at the center of the hub.

Next, measure from the mark you just made to the center of the right hub flange and write down the number. Do the same for the left flange. To double check yourself measure from the middle of one flange to the other. If you add the right and left measurements together it should equal the overall flange width you just measured. Congratulations, that’s all the measurements you need from the hub.

The other things you will need to know are the Effective Rim Diameter (ERD), number of spokes in wheel and the spoke crossing pattern you want to use. You can find the ERD of the rim you want to use by doing an internet search for “ERD of 26” SUN CR-18 rim” for example and you will come up with the answer. I usually check two or three sources to see if they agree.

The spoke count is just how many spoke holes your hub has(hopefully your rim has the same). The cross pattern is how many times a spoke crosses another spoke on it’s way to the rim. If you are rebuilding a wheel that was damaged, take a picture before you unlace it so you can see the cross pattern that was used before. If you are building from scratch, a three cross pattern for a 26” or 700c wheel usually works well. If you are building a 20” or smaller you may want to use two cross or even one cross if you are using a large diameter hub. Check out similar wheels to the one you want to make to see what others did before you.

Now that you have all the information gathered you can finally get down to calculating. I use the spoke calculating program at United Bicycle Institute found at www.bikeschool.com. It will ask ERD, hub flange diameter, hub center to flange center, hub spoke hole diameter(I just use the 2.5 preset usually), number of spokes in wheel and the cross pattern. Just hit calculate and write down the number.

Now go back and change the hub center to flange center number to the other value and hit calculate again. The only thing that might screw you up at this point is if you had a hub with different size hub flanges. You would need to enter the values for the left side, calculate, then reset the hub flange diameter and hub center to flange center for the right side of the hub to get the correct spoke lengths for both sides.

As you can see, there is quite a lot to creating a wheel. We haven’t even begun to lace and true this wheel we are hoping will carry us safely around a corner at 45 MPH. Building wheels is one of the things that has amazed me from the beginning of my bike career. The fact that I can take spokes, nipples, a hub and a rim and create something that weighs a few pounds but can support 250 lbs of rider and bike zooming around a corner still blows my mind.

The best intro to wheel building for a beginner I’ve found is Zinn and the Art of Road Bike Maintenance by Lennard Zinn. I have four other books but that is the one that “clicked” for me. I hope some of you give it a try. Nothing feels better than riding around on something you built yourself!

Bicycle Man

Bicycle Man